What Is Stage Zero and Why Do You Need It?

Posted by Max Rundlett on 7th Aug 2020

This week, we explore the importance of Stage 0 - the not so glamourous but MUCH needed step to safely modifying your Volvo.

What is Stage 0?

Stage 0 is the state of which all electrical and mechanical components of your car’s drivetrain are in reliable, working order. Ensuring that your car’s drivetrain is in good working order is critical in maintaining reliability.

Why is Stage 0 important?

When applying more power, being able to apply that power reliably is what makes Stage 0 so important. Without reliability in the parts you’ve installed and are currently running, you run the risk of ruining critical internals. Bent rods, spun bearings, and burnt valves are all very real possibilities if any parts on this list are neglected to be taken care of.

Included in Stage 0:

Servicing your ignition system is the first step in Stage 0 maintenance. Worn spark plugs may have a gap that is too large, causing misfires. Misfires and ignition knock can lead to carbon build up on your exhaust valves or worse, rod bending preignition.

Refreshed fluids are the key to not only a successful Stage 0, but in keeping your car running right. Going too long without changing your oil can lead to the lubricating properties to break down and increase wear on your engine’s internals. Transmission fluid can heat up and wear out as well, so draining and filling (not flushing) with new fluid maintains those crisp, clean shifts you crave.

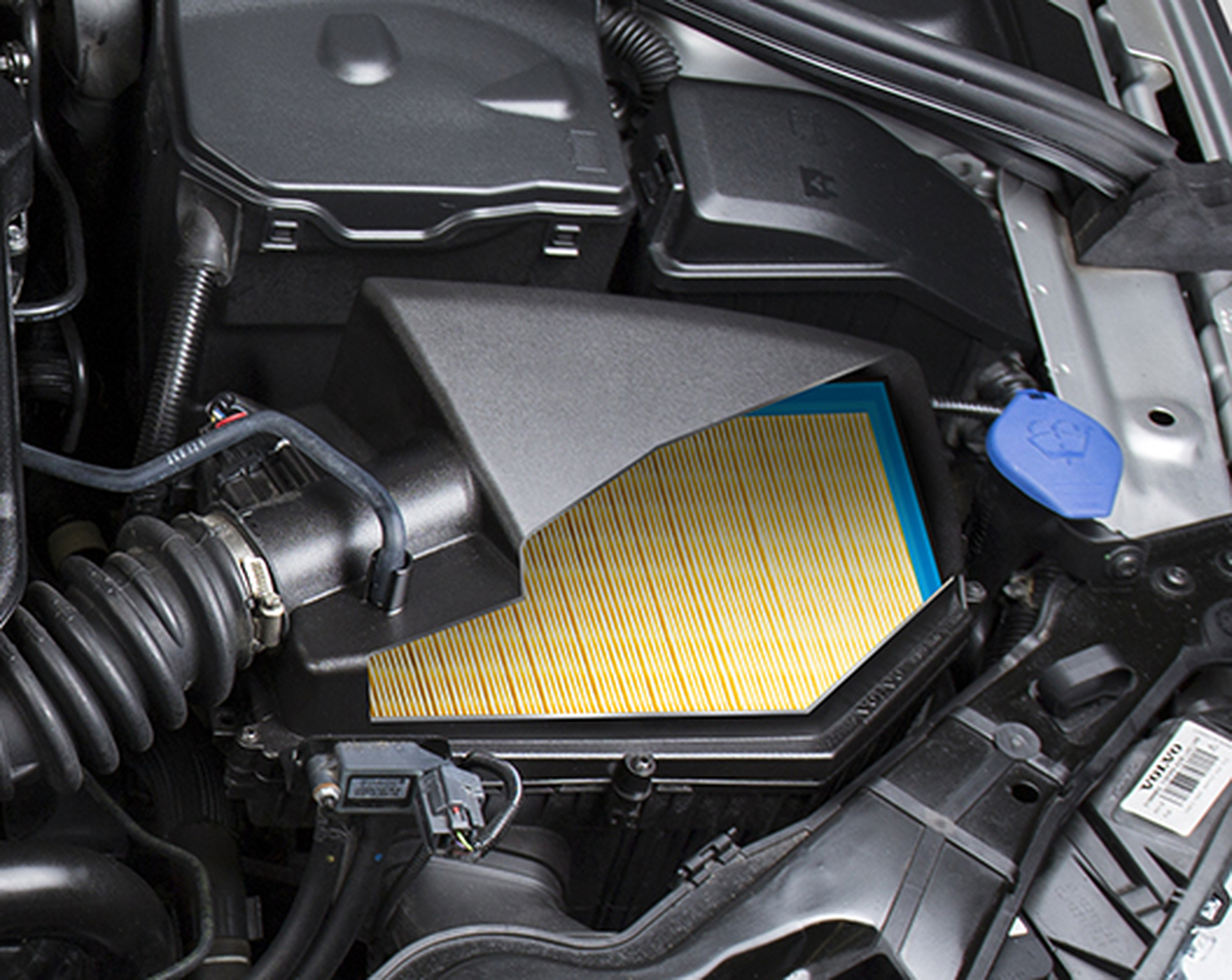

Replacing your various filters is the next step in Stage 0 maintenance. A plugged fuel filter can restrict flow to your injectors or cause them to become clogged with sediment. Your intake air filter can cause similar issues with your turbo or throttle body. A dirty air filter can restrict air flow or send debris hurtling towards your turbo, neither of which is ideal in ensuring longevity and reliability.

- Induction Piping

- Charge Piping

- Vacuum Lines

- PCV Service

Ensuring that your car is breathing properly, whether it be charged air or crankcase pressure, is a necessity. Factory rubber couplers for charge piping are notorious for cracking and splitting, causing boost leaks. Old rubber vacuum lines can also cause boost inconsistencies. A plugged PCV system won't cause any issues with your induction system, but it may cause oil leaks forced by high crankcase pressures. A potentially catastrophic failure if gone unnoticed.

Going along with proper air flow, your MAF (mass air flow) and oxygen sensors are crucial in maintaining proper air/fuel ratios. Failing sensors can cause incorrect readings in the air/fuel ratio. This can lead to issues such as burnt valves due to very hot ignition temperatures.

Building a motor takes time, money, and attention to detail. Don’t let a simple oversight cause catastrophic failure on your project. If you have any questions about building your motor or about Stage 0, don’t hesitate to email us!